Meili vormingu viga

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

resetAccountPassword

forTheAccount

pwdLetterLimtTip

inconsistentPwd

resetSuccess

resetSuccessTips

login

Uudised

best cnc machining service parts in nexus ltd

2022-05-10 17:49:12

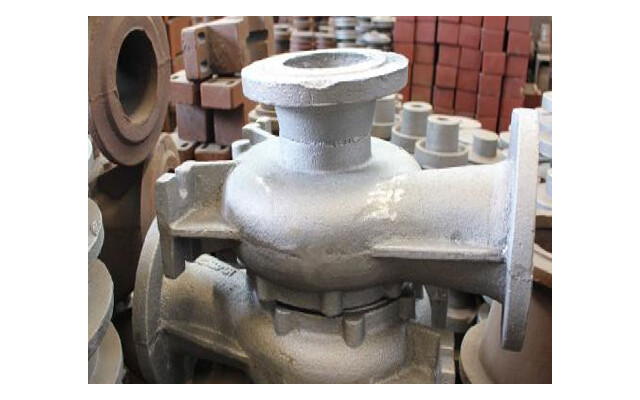

CNC machining is a widely adopted and popular method for some machinery and equipment manufacturing companies, and nexus CNC machining services ltd is no exception. Why does it stand out from many machining methods? And what are CNC machining service parts?

Why choose the CNC machining service?

CNC has many reasons for manufacturers to choose it, but do you know these surprising reasons? Let's take a look now.

Multi-axis linkage centralized processing method

It integrates multiple processing methods and technological processes on one machine tool, which can reduce the total area of the machine tool and save indoor space for the production workshop of CNC machining plants as well as improve processing efficiency and quality.

Intelligent

CNC machining is an intelligent machining method, and there is no need to manually operate the CNC blade in the whole process of machining. High level of automation technology. Effectively improve the quality of CNC machining parts and improve processing efficiency.

Stronger coordination

Compared with traditional machine tool systems, CNC machining has stronger coordination capabilities.

Adaptable

When machining parts, it is more efficient. The adaptability to parts is stronger, and the stiffness is also very high. These features allow manufacturers to respond to today's fierce market and enhance their overall processing capabilities.

High accuracy

CNC has a very strong machining strength and can accurately process a variety of products with different contours. If you have some products developed, indestructible, or urgently needed precision castings.

With so many benefits of CNC machining service, which parts can be machined this way? Which parts are suitable for CNC machining?

Parts with high precision requirements

CNC machining has the important advantage of high precision, so some parts with high precision requirements are very suitable for this kind of machining method. The rigidity of the CNC machine tool is good, the CNC machining is accurate, and the size compensation can be easily performed, so it can process parts with high dimensional accuracy requirements.

Multi-variety small and medium batch parts

The cost of CNC processing and manufacturing has gradually decreased, and you will find that large-scale parts processing has appeared both at home and abroad. If the debugging time of the program and the preparation time of the tooling are shortened, small batches and single-piece production can be processed.

Parts with small surface roughness values

If the tool material and workpiece, tool angle, and finishing allowance are constant, then the feed rate and cutting speed will determine the surface finish. For ordinary machine tools with constant CNC machining speed, the cutting speed of different diameters is also varied. When machining surfaces with different surface roughness, a smaller feed rate is suitable for the surface with small roughness, and a larger feed rate is ideal for the surface with large roughness.

Parts with complex contours

CNC machining has a satisfying arc interpolation function, so any plane curve can be approximated by an arc or a straight line, so parts with complex contour shapes are also very useful.

Minghe has the best CNC machining service parts in nexus ltd, if you are interested, welcome to contact us.

Võta meiega ühendust